Blasting Nozzles

BlastX can supply a range of abrasive blasting nozzles sutable for most abrasive blasting machines.

We currently supply only Venturi Type, long wear life nozzles which can be supplied made with tungsten carbide, sialon or boron carbide.

What Wear Life Can I Expect from My Blast Nozzle?

Wear life of abrasive blasting nozzles depends on many factors, including the type of blast media being used, hardness of the blast media, media particle size, shape, blast velocity etc.

Dustless or water blasting, where the blast media is mixed with water BEFORE it enters the nozzle, can greatly increase the life of blast nozzles, as the water acts as a lubricant, & cushions the impact of the abrasive particles on the blast nozzle liner.

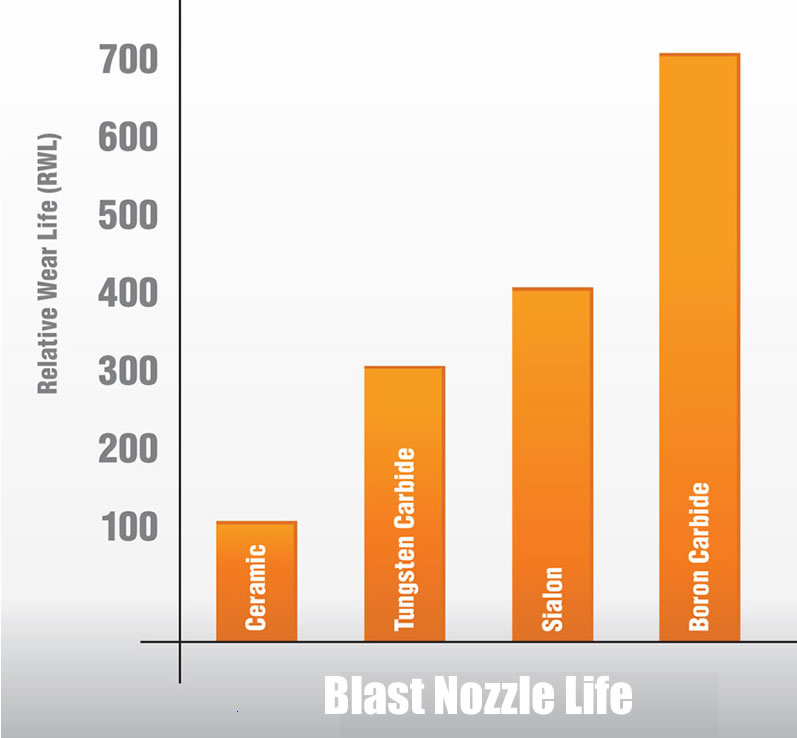

Below is a chart that shows the average expected wear life of the different types of blast nozles. The chart below is for DRY media blasting, & it dosnt show the type of blast media or any other factors that are used to determine the results, so it is to be used as a rough gude only. Your results will probably vary from those shown below.

The blast nozzle life chart illustrates the wear test results conducted by the U.S. Department of Interior and U.C. Berkeley to establish RWL ratings. We currently stock only the Tungsten Carbide & Sialon nozzles, however we can also supply Boron Carbide Nozles on request. Lead time for supplying a Boron Carbide nozzle is aproximately 3 weeks. Note however that the Boron Carbide nozzles can be 3 to 4 times more expensive, for less than double the wear life of the much cheaper Sialon nozzles.

We currently stock only the Tungsten Carbide & Sialon nozzles, however we can also supply Boron Carbide Nozles on request. Lead time for supplying a Boron Carbide nozzle is aproximately 3 weeks. Note however that the Boron Carbide nozzles can be 3 to 4 times more expensive, for less than double the wear life of the much cheaper Sialon nozzles.

We recommend the Sialon nozzles as the best value, with the best dollar to wear life ratio.