Bresle Salt Contamination Test Kit

A Bresle Salt Contamination Test Kit Enables Testing For Chloride Salt Contamination on Abrasive Blasted Surfaces Before Applying the Protective Coating

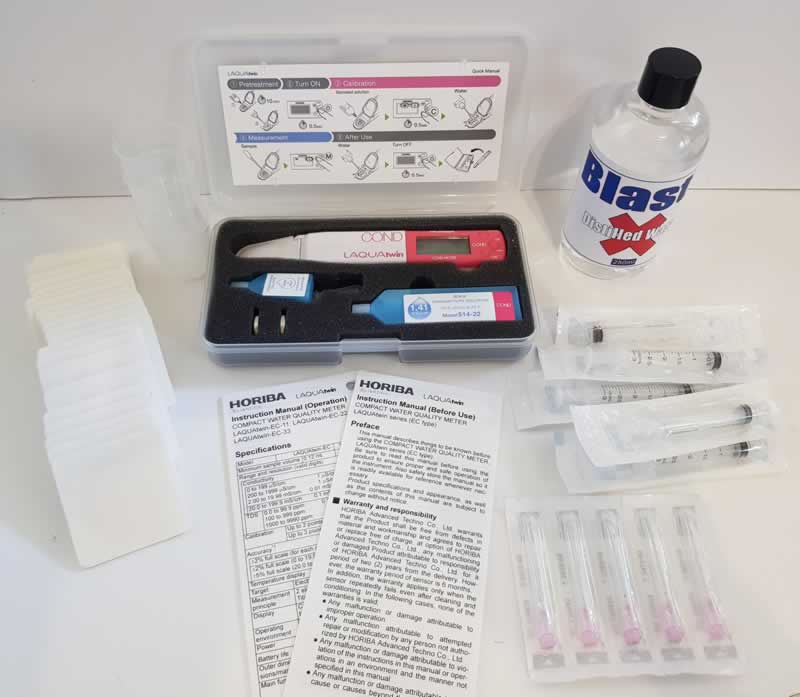

Our BlastX Bresle salt contamination test kit includes everything you need to test for chloride salt contamination on freshly blasted surfaces. It is the perfect partner for BlastX 108 Flash Rust Inhibitor & Salt Remover additive, so you can ensure that your customers are delivered a perfectly clean, ready to coat blasted surface that is free of Chloride salt contamination.

What is Bresle Testing?

Bresle salt contamination testing is a method of testing whereby an adhesive ‘Bresle’ patch is applied to the freshly blasted & cleaned surface so that a sample can be collected to test for Chloride salt contamination of the surface. The Bresle patch contains a ‘chamber’ where distilled or de-ionised water is injected with a syringe.

After a minute or two, the water is drawn back out of the chamber into the syringe, & tested for chloride salt contamination levels with an electronic chloride salt testing meter. The electronic chloride salt testing meter measures the conductivity of the solution, as the higher the amount of dissolved salts is in the solution, the greater the conductivity will be.

This Bresle method of testing was introduced in 1995 in the ISO 8502-6 and ISO 8502-9 standards. The test was developed to measure the soluble salt concentration on freshly blasted surfaces prior to applying the protective coating. Australian standards AS 1627.9—2002 – ‘Metal finishing —Preparation and pretreatment of surfaces’, NAVSEA, US Navy, IMO, & ASTM have also adopted the Bresle salt contamination test method as their standard test procedure for determining salt contamination on freshly blasted surfaces.

Why do I need to Bresle Test for Chloride Salt Contamination?

Chloride salt contamination of the surface prior to applying the protective coating is one of the major reasons for premature protective coating failure. Bresle salt contamination testing is the best way to test if the surface is within acceptable limits for Chloride salt contamination prior to applying the protective coating.

Many major contracts in Australia now also specify that the surface be prepared in accordance with Australian standards AS 1627.9—2002 or one of the other international standards prior to coating.

The contract will usually specify that Chloride salt contamination of the surface must be tested using a Bresle Salt Contamination test kit, & also specify the maximum allowable level of salt contamination that is permissable before the protective coating can be applied.

What is the acceptable limit for Chloride salt contamination?

The International Maritime Organisation (IMO) Performance Standards For Protective Coatings sets the maximum allowable limit for Chloride salt contamination at 50mg per square metre. However the maximum amount of Chloride salt contamination is usually set by the coating manufacturer, or it may be specified by the end user in the contract you have with them.

If no maximum limit has been set by the coating manufacturer or the end user, 50mg per square metre is a good benchmark to work to.

How do Surfaces Become Contaminated With Salt?

Salt often gets into the air as an aerosol, especially near coastal areas. Salt laden moisture from the sea can get blown many kilometres inland, where it gets deposited onto surfaces. Some blasting media can also be contaminated with salt particles.

The abrasive blasting process itself can also drive salt that was already on the surface before blasting, deep into the pores & pits in the metal, making the problem worse.

Why is it important to remove Chloride Salt Contamination before Painting?

Salt contamination on a surface such as steel can cause adhesion problems for any paint or protective coating applied to the surface.

Salt is hygroscopic, & it can draw moisture through permeable surfaces such as paint. This creates a buildup of water molecules between the substrate & the protective coating. The water molecules combine with the salt & other contaminants trapped beneath the coating to form an electrolytic cell, causing corrosion. This causes the paint to blister & rupture, allowing even more moisture to become trapped beneath the surface, & causing the problem to spread.

How can Bresle Salt Contamination Testing help my abrasive blasting or painting business?

By being able to Bresle test surfaces for salt contamination prior to painting, you can apply for contracts that specify that surfaces comply with Australian standards AS 1627.9—2002, or other international standards (such as ISO 8502-6 / ISO8502-9 or US NAVY PPI 63101-000) for acceptably low levels of chloride salt contamination that must be attained before the protective coating can be applied.

However, even if there is no requirement or specification for chloride salt contamination levels by your customer, you can help your customer by explaining the need for chloride salt contamination testing, to ensure that contamination levels are below a specified level, & explain how ensuring that salt contamination is below the specified level, can extend the life of the protective coating & reduce ongoing maintenance costs.

You can use this service to help gain customer loyalty & trust, & also justify a higher price for your services by offering to test for chloride salt contamination, & clean the surface if necessary to bring the contamination down to acceptable levels before applying the protective coating.

If Bresle Testing indictates that Chloride salt contamination is above acceptable limits, how do I remove the contamination from the surface?

Chloride salt contamination can usually be removed from the surface by pressure washing the surface at 1500psi or higher with BlastX 108 Flash Rust Inhibitor & Salt Remover in the pressure washer water at aprox. 100 parts water to 1 part BlastX 108. After pressure washing you should Bresle test the surface again to ensure salt contamination is within acceptable limits. Full usage instructions for BlastX 108 can be found here or download the usage instructions as a PDF.

What’s Included in the BlastX Bresle Salt Contamination Test Kit?

Contents of the kit include:

- 1x Horiba LAQUAtwin EC22 Compact Conductivity Meter (Japanese made quality)

- 1x Horiba replaceable sensor

- 2x Calibration Solution

- 1x Conditioning Solution

- 1x Pipette

- 2x CR2032 batteries

- 25x Bresle Test Patches

- 5x 3ml Syringe

- 5x Blunt Needle

- 1x 250ml bottle distilled water

- 2x Horiba LAQUAtwin Instruction manual (1x Before Use, 1x Operation Manual)

- 1x Bresle Salt Contamination Test Kit Usage manual

- 1x Case for conductivity meter

- 1x Carry Case

The conductivity meter is the most important aspect of the Bresle Salt Contamination Test kit. We have chosen the Japanese made Horriba LAQUAtwin EC22 Compact Conductivity Meter, for superior accuracy, reliability, & longevity.