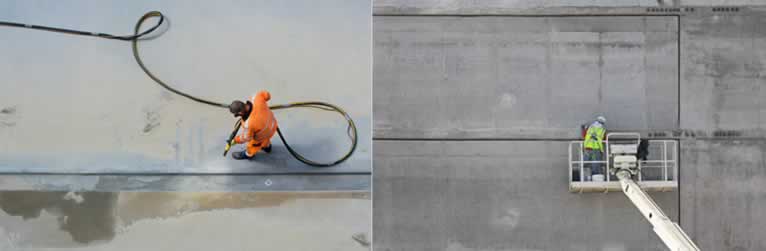

Wet Blasting Flash Rust Inhibitor / Salt Remover for Dustless / Vapour Blasting

Do you own a Dustless or Vapour Blasting business? Need a cost effective Wet Blasting Flash Rust Inhibitor & Salt Remover solution?

BlastX 108 can be used as a direct replacement for HoldTight 102, Dustless Blasting Rust Inhibitor, or Hold Blast wet blasting flash rust inhibitor & salt remover additives. BlastX 108 is also made right here in Australia, not overseas like all the above rust inhibitor additives.

Because BlastX 108 can be used as a direct replacement to any of the above flash rust inhibitor products, there is no need to change the dilution ratio or method of use. Simply continue to use BlastX 108 exactly as you would any of the above wet blasting flash rust inhibitor/salt remover additives.

Are you currently using a competitors product, such as one of the brands listed above? We guarantee that BlastX 108 will work as well as your current wet blasting flash rust inhibitor additive, at the same dilution ratios, or your money back!

Safe to use, safe for the environment!

BlastX 108 is Non-Acidic, Biodegradable, Non-Solvent, Non-Flammable, & Non-Hazardous to use when diluted for use. BlastX 108 leaves no residue, & can be diluted at 100:1 – 250:1 dilution ratio when used in the Blast Pot, & in the final cleanup water when pressure cleaning off the abrasive blasting residue.

When used in accordance with the usage guide, BlastX 108 prevents flash rust for 48-72 hours, or often much longer in the right weather conditions.

A cleaner surface means far longer coating life, & far less ongoing maintenance!

In addition to preventing Flash Rust from occurring, BlastX 108 also cleans the surface of all salts, chlorides, nitrates, oils & other blast residue, leaving a perfectly clean surface ready for applying the protective coating.

Most protective coatings begin to fail from underneath, due to contaminates such as salts or chlorides attacking the surface from beneath the coating, or from a lack of adhesion due to oils or other residues left on the surface prior to applying the protective coating.

A thoroughly clean surface provides far greater adhesion for the protective coating, greatly prolonging the life & performance of the coating, & protecting the painted surface far more effectively. This means far lower maintenance costs! And unlike most cleaning solutions, which can cause problems of their own if not completely rinsed off the surface, BlastX 108, leaves ZERO residues when used according to the Usage Instructions sheet.

Note that while there may be other cheaper rust inhibitors on the market, many of these cheaper formulations leave behind a chemical residue, which WILL shorten the coating life.The chemical residue can prevent the coating from adhering properly, & can also cause blistering as the chemical residue attempts to rise to the surface.

The complex formulation of BlastX 108 leaves almost ZERO residue on the surface, greatly increasing the performance & life of protective coatings.

Not just for Dustless, Vapour or Wet Blasting – Use after Dry Blasting or Acid Bath rust removal as well!

Do you do dry abrasive blasting? Or what about acid bath rust removal?

We have you covered as well. BlastX 108 can be used as an after-wash additive to prevent flash rust / rust back. In addition to preventing flash rust / rust back, BlastX 108 will remove all blasting residue, chlorides & salts, & neutralise any acid residues from the surface. The result is a perfectly clean surface that will greatly increase the adhesion & extend any protective coating life applied to the cleaned surface.

Available in either 4kg jerry cans, 20kg cube drum containers, or 210kg drums, we can ship BlastX 108 flash rust inhibitor / salt remover additive almost anywhere within Australia. Order today from our online shop!

Label Image (hover over image to zoom):